A machine that once quietly filled the bin can suddenly become noisy, slow, or produce ice that no one wants to put in a drink. Many people jump straight to repair calls or replacement. In a lot of cases, hard water coats internal parts with mineral deposits. A clear descaling routine solves that problem and keeps the appliance reliable for years.

3 Signs Your Ice Maker Is Screaming for a Descale

Even careful owners often wait until something feels very wrong. Watching for a few early signs helps you act before performance drops too far.

1. Ice Looks Cloudy, Brittle, or Tastes Off

If cubes look milky, crack easily, or bring a strange taste to drinks, minerals are likely collecting on cold metal surfaces. Hard water leaves a chalky layer that disrupts how water freezes and flows. Because ice is treated as food in safety rules, any change in clarity and flavor is worth taking seriously.

2. Production Is Slow or the Bin Never Fills

Another warning sign is a bin that stays half empty even though the unit seems to run all day. Scale narrows water passages and coats evaporator plates. Studies on fouled heat exchangers show that even a thin layer can reduce heat transfer and extend cycle times. At home, that feels like a machine that runs constantly but never keeps up with demand.

3. The Cabinet Runs Hot and the Unit Never Seems to Rest

Pay attention to sound and temperature. When internal surfaces are insulated by scale, the refrigeration system has to work harder and stay on longer. Maintenance reports link that extra workload with higher energy use, warmer housing, and a higher risk of breakdown. If the housing feels unusually hot or the hum never stops, a full cleaning and descaling session is overdue.

Why Is Descaling Crucial?

Descaling is not just about looks. It affects efficiency, hygiene, and the lifetime cost of owning the appliance.

Efficiency and Energy Cost

Mineral buildup acts like insulation on cold surfaces. Research on scaled heat exchangers shows clear drops in heat transfer and higher energy use once deposits form on tubes and plates. For a household or small business, that translates into longer cycles and higher power bills for the same amount of ice.

Hygiene and Safety

Health departments and the FDA treat ice as food, which means surfaces in the water and ice path should be maintained like other food-contact equipment. Minerals create rough patches and crevices where biofilm can cling. Regular descaling, followed by sanitizing, keeps those surfaces smoother and easier to keep clean.

Repairs and Equipment Life

Service firms frequently list water quality as a major cause of ice equipment failures, with limescale at the center of many calls. A basic descaling routine is inexpensive compared to emergency repairs, lost business during downtime, or replacing a unit that was pushed too hard in dirty conditions.

How to Descale a Countertop Ice Maker

Compact ice makers are designed so owners can handle routine cleaning. The key is to follow the manual and work patiently step by step.

Unplug, Empty, and Clean Removable Parts

Unplug the unit. Take out the basket, scoop, and any removable covers. Drain the reservoir through the drain plug or by gently tipping the cabinet over a sink. Wash the loose parts with warm water and a little dish soap, then rinse well and let them dry.

Prepare an Approved Descaling Solution

Mix a descaling solution that your manual allows. Many household care resources recommend distilled white vinegar mixed with water for small appliances, often at equal parts for internal plumbing and a weaker mix, such as 1:10, for wiping surfaces. Avoid harsh chemicals or abrasives unless the manufacturer clearly approves them.

Fill the Reservoir and Run a Cleaning Cycle

Pour the solution into the reservoir up to the fill line. Use the cleaning or self-clean function if your model has one, so the pump circulates the liquid through the internal water path and across the cold plate. If there is no special mode, run several regular ice-making cycles and discard all ice that forms.

Give It Time, Then Drain and Rinse Thoroughly

When there is visible scale, a short soak inside the machine can help loosen deposits, as long as it stays within the time limit in your manual. After that, drain the solution completely. Refill with fresh water, run a short cycle, and discard the water and any ice. Repeat the rinse until there is no vinegar smell or taste.

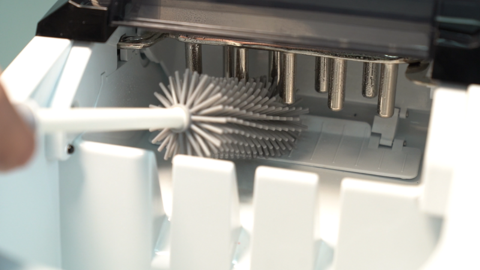

Wipe, Dry, and Reassemble the Ice Maker

Wipe interior walls and the exterior cabinet with a soft cloth and a mild cleaning mix, then dry all surfaces. Reinstall the basket and scoop, make sure everything is seated correctly, and plug the machine back in so it can return to normal use.

Tips for Descaling Under-Counter & Commercial Machines

Larger under-counter and commercial ice makers handle more water every day and have more complex internals. The basic idea is the same, yet the process often needs more care.

- Shut off water and power before removing any panels.

- Use a descaler labeled as safe for the metals inside the unit, such as nickel-plated or stainless components.

- Mix the chemical at the concentration listed on its label and follow the unit’s manual for routing it through the system.

- After contact time, flush with several rounds of clean water to remove any residue.

- Run a separate sanitizing step on bins and contact surfaces, because descaling focuses on minerals, not microorganisms.

- For high-volume locations, consider scheduling this work with a qualified technician so descaling, sanitizing, and mechanical checks happen together.

How Often Should You Descale Your Ice Maker?

There is no single schedule that fits every kitchen. Water hardness, daily usage, and ambient temperature all matter. Appliance brands and commercial service firms often suggest internal cleaning and descaling at least twice per year, with shorter intervals in hard-water areas or high-demand sites.

You can use this simple table as a starting point:

| Situation | Suggested descaling interval* |

| Home, soft or filtered water | Every 6 months |

| Home, noticeable hard water | Every 3 to 4 months |

| Small office or café | Every 2 to 3 months |

| Busy bar, restaurant, or hot climate site | Every 1 to 2 months |

*Adjust to the instructions in your manual, local health rules, and what you actually see: cloudy ice, slower production, or visible deposits are all reasons to clean sooner.

Pro Tips to Prevent Limescale Buildup

Prevention reduces how often deep descaling is needed and keeps performance stable.

- Use filtered or softened water whenever practical to reduce mineral load.

- Replace water filters on the schedule printed on the cartridge or in the manual.

- Empty and dry the reservoir if the unit will sit unused for several days.

- Wipe interior surfaces regularly with a soft cloth and a mild cleaning mix.

- Keep the cabinet level and leave enough space around vents for good airflow.

These small habits make each future cleaning easier and help the system stay closer to its original output.

Keep Your Ice Maker Clean for Better-Tasting Ice Every Day

Clear, fresh ice depends on clean metal surfaces and open water paths. Limescale quietly interferes with both, but it responds well to simple, regular maintenance. Watching for early warning signs, following a safe descaling routine, and matching the schedule to your water quality keep drinks tasting better and protect the appliance you rely on. A calendar reminder every few months is a small step that avoids a lot of frustration.

FAQs About Ice Maker Maintenance

Q1. My unit is running but not making ice. Could scale be the cause?

Mineral deposits can clog inlets and coat cold surfaces, which stops water from freezing or moving correctly. Low water pressure, blocked filters, or faulty sensors can look similar. If descaling does not help, use the troubleshooting chart in the manual or call a qualified technician.

Q2. Can I use vinegar instead of a commercial descaler?

Distilled white vinegar mixed with water is widely used on small appliances. Always check that your model allows acidic cleaners, avoid very strong mixes, and rinse repeatedly until any sour smell or taste disappears from the ice.

Q3. What is the difference between cleaning, descaling, and sanitizing?

Cleaning removes visible dirt from bins and panels. Descaling targets mineral deposits in the water path and on cold surfaces. Sanitizing uses a food-safe chemical to reduce microorganisms. A good maintenance routine uses all three at the intervals suggested in the manual.

Q4. If I use filtered water, do I still need to descale the machine?

Filtration helps a lot, yet most treated supplies still contain dissolved minerals. Over time, they can still leave a layer on internal surfaces. You can stretch the gap between descaling sessions, but skipping them entirely increases the risk of slower production and off-tasting ice.

Q5. Is it safe to serve ice immediately after descaling?

It is better to discard the first batches. Drain the solution, refill with fresh water, run several cycles, and throw away all ice made during that flush. Once there is no chemical smell or aftertaste, you can return the unit to normal use.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.